How to Start a Laser Cutting Business

Are you thinking of starting a laser cutting business?

Laser cutting can be a very lucrative line of work, it can also be overwhelming.

So I'm sharing everything you need to know to start a laser cutting business.

Let's start this conversation saying I'm not a laser cutting expert.

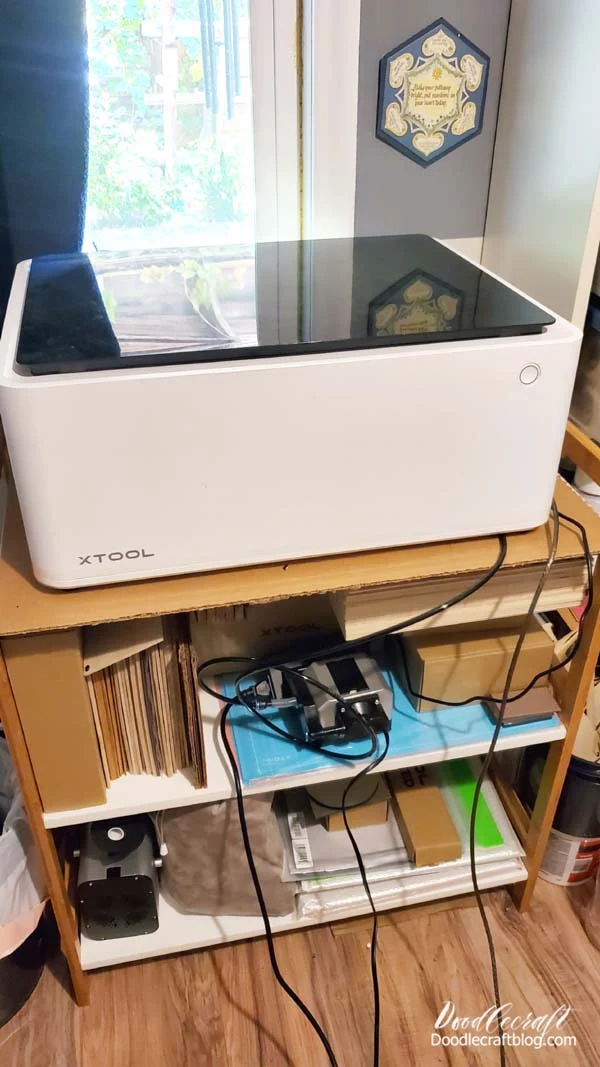

I have one laser cutting machine, the xTool M1 10W Deluxe RA2 Pro and I absolutely love it!

I work with xTool and have affiliate links in this post, however, I am doing my best to make this post very subjective and unbiased.

If you purchase from my links, thank you so much, that's how I can keep offering so much information!

Check out this xTool Small Business Guide

xTool Machines:

xTool F1 Portable Laser Cutter

xTool M1 10W Deluxe RA2 Pro (this is the one I have!)

I'm not running a full time business with my laser cutting.

However, I DO know a lot about running a small business, and a creative one at that.

I'm sharing everything I know here to give you the best information.

Be sure to do your research.

I hope you can get some valuable pointers from this post and make the best move for your business.

Leave your suggestions in the comments and I'll update the post regularly.

**This post will primarily focus on xTool and Glowforge, because they are the industry leaders right now, but there are many other brands and options when it comes to home laser cutting machines...again, do your research on individual machines**

Customization is king!

Everyone wants to buy everything customized these days.

Engrave, Cut, Draw.

Create rubber stamps, acrylic displays, cut wood, cardboard, acrylic, engrave metals, engrave glass, customize everything!

Build, decorate, customize.

Laser Cutters are a big game changer.

I have a Cricut and love love love it, but the laser cutter has opened up a whole new realm of possibilities! (Check this post for starting a Cricut Business from Home)

The xTool M1 is a hybrid, which means it has a cutting blade and mat option that can make it more economical than multiple machines.

Thinking about starting a Laser Cutting Business?

"The master has failed more times than the beginner has even tried" --Stephen McCranie

Do it.

Start a Laser Cutting Business.

Here's a few tips to get started:

- If you have a laser cutter---use it! yes, there is a learning curve but it is worth the ups and downs to get going.

- Don't quit your day job...yet.

- Read your State website about starting a small business.

- Take a Business course at a local college...or check out this FREE Business Course by the Church of Jesus Christ of Latter-Day Saints.

- Determine overhead costs.

- Start Slow, this in not a 'get rich quick' scheme.

- Watch Youtube videos and read posts on other people's experiences.

- Write up a business plan.

If you are just starting this as a side hustle, these are still important steps to take to make sure you are making more than you are spending.

What can you do with laser cutters?

Don't have a laser cutter but are looking to get one?

Research all about laser cutters, as there are differences.

Know what you are investing in, how to care for it and how long you can expect it to last.

Some of the things laser cutters can do:

- Cut and engrave leather

- Cut and engrave basswood/plywood (up to 6mm or so)

- Cut and engrave acrylic

- Cut and engrave rubber stamps

- Etch Stainless Steel Water bottles and Tumblers

- Etch Rock, Stone and Slate

- Etch Glass

- Cut felt, paper and foam

- Engrave on fabric

Laser Cutting Lasers

Consider which Laser Cutter is right for you.

There are many Laser Cutting machines on the market and it's important to know the differences and do some research.

Some laser cutters are enclosed, which is excellent for safety/eye protection.

Some lasers are open and can be set right on the surface to engrave, cut or etch.

There are a few different types of lasers:

We'll only touch on these three types of lasers: CO2, Diode and Fiber

(This xTool post is helpful in breaking down the 3 types of lasers)

DIODE

Diode lasers are a light emitting diode that focuses the light in a narrow point with a lens.

Diode are the least expensive, and they have their limitations.

xTool M1 10W ($1399) and Glowforge Aura ($1199).

They are unable to cut clear, white, blue and transparent colors of acrylic.

Can't engrave clear glass, (although some people find their way around this by painting the glass with tempera paint).

They move slower than the CO2 lasers.

These machines are perfect for the home crafter or hobbyist.

Many people make a great side hustle income with their diode lasers.

The xTool M1 is also a hybrid unit, so it has a cutting blade and can compete with electronic cutting machines.

Materials Diodes can cut: solid wood, plywood, MDF, felt, leather, paper, dark cast acrylic.

Materials Diodes can engrave: solid wood, plywood, MDF, leather, paper, some opaque acrylic, dark glass, stone/ceramic/rock/brick/marble/jade/shale/cement, plated and coated metal, and fabric.

Lifespan for the diode laser is approximately 25,000-50,000 hours.

CO2

CO2 lasers use high voltage power to charge gas to create a infrared light, focused through mirrors and a lens, creating a powerful beam.

CO2 Lasers are much more versatile in their cutting acrylic capabilities.

But they come with a much larger price tag.

xTool P2 Machine ($4499) vs Glowforge Plus ($4995) vs Glowforge Pro ($6995).

They are much faster than a Diode laser.

These machines are awesome for the home crafter and small business owner.

They make production faster with more options for growth.

Materials CO2 can cut: solid wood, plywood, MDF, felt, leather, paper, all colors of acrylic, glass, foam, and rubber.

Materials CO2 can engrave: solid wood, plywood, MDF, leather, paper, all colors of acrylic, glass, rubber, stone/ceramic/rock/brick/marble/jade/shale/cement, plated and coated metal, and fabric.

Lifespan for the diode laser is approximately 5,000-8,000 hours.

FIBER

Fiber will actually cut and engrave some types of metal.

Fiber lasers travel through fiber optic cables or fiberglass that amplifies the beams with the presence of rare earth metals.

Much Pricier machine ($15,000 to $20,000).

Great for big business, not typically for side hustle, hobbyists or small business.

Fiber lasers have a long lifespan, approximately 100,000 hours.

What else do I need with my Laser Cutter?

Make sure when researching machines, you research the workable size.

You want to make sure you have the space to do what you are dreaming of.

Laser Cutting machines have their add-ons...lots of add-ons "needed" or at least really, really desirable.

Machines can come pretty bare and basic.

Adding air filters, honeycomb risers, air assist tools, cup holder/turners, etc all add more to the cost of the investment.

I always suggest buying a "bundle" package, since that gets you materials to get started with immediately.

If you are thinking about the xTool M1 10W Deluxe RA2 Pro, add on the air assist too, it's a game changer. (here's my youtube video about installing the air assist into the xTool M1)

I don't know much about add-ons for the Glowforge, but I'm assuming there are some.

The xTool RA2 is the base and risers for holding cylinders, so you can engrave glass, tumblers and other round things.

LASER CUTTING MATERIALS:

I cut a lot of basswood.

I love the smell of it.

It's super versatile and works for all kinds of projects.

All the acrylic, leather and rubber stamp materials I've used are directly from xTool, so I can make sure they are compatible with my machine.

Have loads of cardboard on hand for practice cuts--or finished products like these butterfly wings!

Files needed for laser cutting.

Cutting and Engraving materials from xTool or Glowforge can be pricy.

Glowforge has a subscription library for files that costs $50 per month or $600 per year (sometimes sales are available).

Join Supportive Laser Cutting Facebook Groups for jig files, suggestions, and free files.

Many facebook groups offer free vector files for laser, join groups and save them off.

Search and Ask Questions on the facebook groups, most people there are willing to share their expertise, trials and errors and even laser cutter settings to help ensure the best possible outcome.

Here's one just for the xTool M1 users: xTool M1 Official Group

Any file type can be imported into the laser cutting design software, but then usually needs some tweaking, outlining, etc.

If you aren't skilled with graphic design software, it can be overwhelming.

I find that the xTool Creative Space (FREE) Software is perfect for everything I need to do with my xTool M1.

I use photoshop primarily to design my graphics and images and then import them as png's into XCS.

If I purchase files online, the DXF files are right for the xTool, but sometimes need the image selected and changed from engrave to cut, etc.

Purchased files usually work easily, but some may take trial and error.

Keep lots of cut up pieces of cardboard on hand--practice your cuts, patterns and files on cardboard before using expensive materials.

What to Make to sell!!!

Deciding what to make can be tricky, every audience is different.

What sells for me, might not be a big money maker for you.

Depending on where you are selling can make a difference too.

Here's a few places to find easy Laser Cutting Files that are a GREAT first start to projects and learning your machine:

- Design Bundles (frame below is from here)

- Hungry Jpeg

- Creative Fabrica

- Etsy

- Free Vectors for Laser Cutting

- Cool Laser Cut Vector Files (FB Group)

- xTool Free Project Files

BEST SELLERS

- Earrings

- Coasters (cork and slate)

- Keychains

- Ornaments

- Cutting Boards

- Wood Signs

- Engraved Glasses

- Etched Tumblers

- Engraved Silicone Tumblers or Watch Bands

- Hip Flasks

Other ideas: engraved hammer handles, wooden spoons, canvas, stocking name tags, luggage tags, leather hat patches, wood signs, trinkets, boxes, miniatures, rubber stamps, etc.

My BEST SELLERS are always the $10 or LESS table!

I like to have a few big ticket items, $20-$50 tumblers, Wood signs, other big eye catching things...but the "under 10 bucks" table always does the best.

All those little "micro" transactions add up (it's the pay-to-win logic from every game app).

Marketing yourself

Don't worry, the market isn't flooded.

There's ALWAYS room for another GOOD restaurant on the block.

Find your niche with laser cutting and make your name in the world.

Contact local pubs and bars and get gigs engraving coasters and glasses or other merch.

Solicit gift shops or local stores and arrange a deal to do their custom merch.

Search for local artisan stores, these are increasingly popular, and you can sell handmade goods by giving a commission to the store.

Email local college, businesses, Insurance companies, hospitals, etc and see if you can have them as clients for custom logo engraving and merchandise customizing.

Find a local leather worker and partner on projects together.

Use Social Media--start an Instagram, TikTok, Facebook, YouTube and Pinterest account.

Use all of them, they all hit different demographics.

Yes, this part is hard work...you become not only the creator of goods, but the photographer, the content creator, the model, the salesman.

Hire parts out, hire your teenage kids to do it, make it a family project with a goal in mind.

PRICING:

What Should I Charge?

This is a very broad topic.

I always charge double of what I immediately think. (like for an etched tumbler, I think $20 and say $40...if they take it, I'm good!)

I charge enough that I am thrilled to make the item, instead of feeling grumpy about it...or like it's wasting my time.

Here's a good formula:

It mostly comes down to what you feel your time is worth.

You have to be brave, value your worth, and come up with a price you feel good about.

A price that makes you feel giddy inside while you are making the item.

GET A BUSINESS LICENSE:

File a DBA with your city so you are covered selling.

Every state has different rules and regulations about business starting, so find your state website and see what it takes.

Mine was easy to set up and not too expensive, and I am set up as an LLC. (Varies between $10-100)

You will also want an EIN number or Tax ID number.

This will make it so you can buy things from wholesalers.

This should also set you up to pay taxes to your state every year.

Check the regulations on taxes for your state and county.

I pay my sales taxes yearly after calculating profit for the time period.

Higher an accountant if you need help with bookkeeping or filing taxes.

Keep track of all your income, even yard sales, booths online sales and friend sales.

Keep track of all your expenses, even printer ink, paper, booth fees, materials and the portion of your home/power/internet used for your business.

Work with the same tax people yearly, for ease of filing taxes.

First Timer Tips:

- Start with one product at a time

- Know your market

- Don't undersell yourself

- Don't expect to get rich quick

- Make one item and show it to others, if someone wants you to make them one--make this your first product

- Don't give up

- Do not sell items with copyrighted images, designs, etc. (NO DISNEY or other licensed media, these guys will come after you and shut you down...don't do it.)

How to set up space for your Laser Cutting Machine

Vent through window or have an air filter box for venting.

Big surface machine needs a big surface to sit on.

Make sure you measure your space with a tape measure and make sure it will work.

The Laser Cutter will likely need to plug into your computer via USB, so make sure it's in a place that can connect...or like me, run a 25 foot USB cord to the computer from the laser cutter.

Finding a shelf or cart for the Laser Cutter makes it convenient to store materials underneath, here's some I like:

(Check measurements and make sure your machine will fit and decide if you want your station to have wheels or not)

Where to Sell???

They say a person needs to see an item 13 times before they decide to buy it.

So marketing is key.

There are lots of places to sell hand crafted products.

Here are some ideas:

(bonus, use more than just one of these...you want as many streams as possible)

- Etsy

- Flea Markets or Swap Meets

- eBay

- Amazon Handmade

- Facebook Marketplace

- Local Classified Ads

- Farmer's Market

- Holiday or Seasonal Boutique

- Artisan Collective

- Facebook, Instagram, TikTok

- Shopify Website

- Business Website

- Word of mouth

- Family and friends

- Email list

- Conventions/Vendor Events

- Store front

- Shared space of a store front

- Ask store front to carry your products

Booths and Events.

Lots of people love selling at boutiques, farmer's markets, events, conventions, etc...the type of place you need inventory, tables and displays and lots of helpers!

Typically you get a 10x10 or 10x20 space to set up your stuff. Buying in to the event can cost anywhere between $10 to more than $1000.

The event will advertise and get lots of your customers there, especially if they are well established events (i.e. Pinners, Comic Conventions and Fairs).

There are typically discount codes for you to offer your customers if they attend the events as well and there can be kickbacks for you if people use your code.

Events can be extremely lucrative--if that's your vibe.

Lots of people love selling at boutiques, farmer's markets, events, conventions, etc...the type of place you need inventory, tables and displays and lots of helpers!

Typically you get a 10x10 or 10x20 space to set up your stuff. Buying in to the event can cost anywhere between $10 to more than $1000.

The event will advertise and get lots of your customers there, especially if they are well established events (i.e. Pinners, Comic Conventions and Fairs).

There are typically discount codes for you to offer your customers if they attend the events as well and there can be kickbacks for you if people use your code.

Events can be extremely lucrative--if that's your vibe.

TIPS For Doing Booths or in-person Events:

- Price EVERY item (unless everything is the same price--which I've also done before)

- Don't make people ask you what the price is...they wont.

- Have a full table of items $10 bucks and under--and make sure people know that's the bargain spot.

- Make your set up visually pleasing.

- Offer Custom work and have business cards on hand.

- Sell at boutiques/markets that are applicable to your items (like if you sell D&D dice sets, go to a Comic/Gamer convention...go where YOUR people are)

- Make sure you can ACCEPT electronic payments, venmo isn't always enough, especially if the internet is spotty. (Get the Square or PayPal Business App and reader)

- Have weights or sandbags to hold down the tables, plan for inclement weather.

- Get stretchy tablecloths that go under the legs of the table so they won't blow away or up in the breeze.

- Find out if you will have access to electricity. (Bring fans if it's hot)

- Offer something FREE or a discount if they immediately start following your social media.

If you have a portable Laser Cutter, like the xTool F1, you can offer custom engraving on the spot!

Vendor booths are fun for some people!

They love the excitement of set up and interacting with people and selling their products.

Vendor booths slots can be pricy, ranging from free to $1000+ just for a 10x10 foot space.

So do your research and make sure you can profit after all is said and done.

If you are doing in-person events, you need to have lots of inventory...which means you need a place to store it, a way to display it and something to do with it after the event is over.

Likely you won't sell out, so planning a few events consecutively is hard work but pretty nice way to really thin out the inventory.

I do not love doing vendor booths.

I've done several, and I actually enjoy them...but I don't love the set up, the hauling stuff around and the clean up.

I have ALWAYS made more money than spent, making them all profitable, but still not my favorite way to generate income.

You'll have tons of people walk up and look at your well made items and say "I could make that" and then leave.

It's can be a bit frustrating.

Lots of looking and few sales.

If you are going this route, make 90% of your items cost less than $10.

People are much more likely to commit if they are impulse item prices.

Have a whole table of $10 and under products!

Have a few items that cost more, are impressive and large...but just a few of them.

Make sure to have business cards too--so people can follow up if they want something large or personalized.

PRO TIP:

Offer a perk if they follow you on social media immediately, like a discount on one item or a free keychain or something.

This way they can continue seeing your products--more than 13 times and think about buying more often.

Have a way to purchase online--Etsy or Shopify website are my favorites and link to your shop as much as you can.

Phew!!! That's it!

That's a lot.

I know.

There is a lot to think of and research before investing in and starting a Laser Cutting Business.

As with any business, there is risk and the ups and downs.

Some months will be great and others really lean (I'm looking at you February!)

I hope I gave a broad scope of information so you are much more eductated in your planning and decision making process.

If you have any specific questions or if this helped you out, leave me a comment!

Thanks!

-min.jpg)

.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

.jpg)

-min.jpg)

.jpg)

-min.jpg)

-min.jpg)

Comments