Beginners Quick Guide to xTool S1 Laser Cutter Setup

Investing in an xTool Laser Cutter is a great decision marking a strategic move for both hobbyists and professionals alike.

Mastering the intricacies of the xTool laser cutting machine comes with a challenging learning curve and takes patience and time. Users must navigate the features and settings to achieve precision and proficiency in crafting.

Having home laser cutting technology offers a lot of benefits that make it a valuable asset in various creative and manufacturing endeavors--thinking of getting an xTool Laser Cutter?

Have you already purchased one?

Let's get started with basic xTool information, basic xTool setup and all the frequently asked questions about xTool.

xTool Machines: (affiliate links)

- CO2 Laser xTool P2 Machine

- xTool F1 Portable Laser Cutter

- xTool S1 20W or 40W ( I have the 20W--see this post)

- xTool M1 10W Deluxe RA2 Pro (this is the one I have--see this post)

Commonly Asked xTool Questions:

What is xTool?

XTOOL is a Chinese Company. (xtl us inc.)

Established in 2010, XTOOLTECH is an automotive intelligent diagnostic supplier based in Shenzhen, China.

xTool has awesome customer support and works quickly with customer issues, just have a little patience for time zones to line up.

PRO TIP: Join the Official xTool Facebook Groups for the BEST question and answers, support and settings, and a great community of like-minded folks.

There are multiple xTool machines, including xTool S, xTool D, xTool F, xTool M and xTool P.

Why Buy an xTool?

Add the precision of the xTool Laser Cutter into your life for a side hustle, personal home projects or for small business owners.

The amazing machine's ability to execute intricate cuts with utmost accuracy is unparalleled, allowing users to bring their designs to life with exceptional detail.

Whether crafting intricate patterns on paper, engraving on wood, or cutting precise shapes from acrylic, the xTool Laser Cutter ensures a level of precision that sets it apart in the realm of crafting and design.

Versatility is another key advantage. The xTool Laser Cutter accommodates a wide range of materials, from wood and acrylic to leather and fabric.

This versatility opens up endless possibilities for creators, enabling them to explore diverse projects without the need for multiple specialized machines.

The ability to seamlessly transition between materials enhances the xTool S1's utility and makes it a go-to tool for various applications.

Speed and efficiency contribute to the xTool Laser Cutter's appeal. Its swift cutting and engraving capabilities save valuable time, allowing users to increase their production output without compromising on quality.

This efficiency is particularly beneficial for small businesses and entrepreneurs looking to scale their operations while maintaining a high standard of craftsmanship.

User-friendly features make the xTool Laser Cutter accessible to both novices and experienced users.

Intuitive software interfaces, precise controls, and automated functions streamline the crafting process, reducing the learning curve and ensuring a smooth workflow.

This accessibility makes the xTool Laser Cutter an excellent choice for those entering the world of laser cutting technology.

Additionally, the durability and reliability of the xTool Laser Cutter contribute to its long-term value.

Built with quality materials and robust engineering, this machine is designed to withstand the rigors of regular use, providing a dependable tool for years to come.

Investing in an xTool Laser Cutter is a smart choice, combining precision, versatility, speed, user-friendliness, and durability.

Whether pursuing creative projects or running a small business, this cutting-edge technology empowers users to elevate their craft and unlock new possibilities in the world of laser cutting and engraving.

TEN REASONS TO BUY AN XTOOL LASER CUTTING MACHINE:

- Precision Cutting: Achieve intricate designs with the xTool's precise laser-cutting capabilities.

- Versatility: Cut various different materials, from wood to acrylic, expanding your creative possibilities.

- User-Friendly: Despite its advanced features, the xTool is designed with user-friendly interfaces for easy operation.

- High Quality: Benefit from the xTool's durable construction and high-quality components.

- Efficiency: Save time with the xTool's efficient cutting process, streamlining your projects.

- Customization: Create personalized designs with ease, making each project uniquely yours.

- Learning Curve: The xTool accommodates users of all skill levels, making it suitable for beginners and experienced crafters alike.

- Safety Features: Built-in safety features ensure secure usage, offering peace of mind during operation.

- Support and Community: Access a supportive user community and resources for assistance and inspiration.

- Durability: Invest in a long-lasting tool that withstands regular use, providing value for your investment over time.

Setup the xTool S1 Laser Cutting Machine:

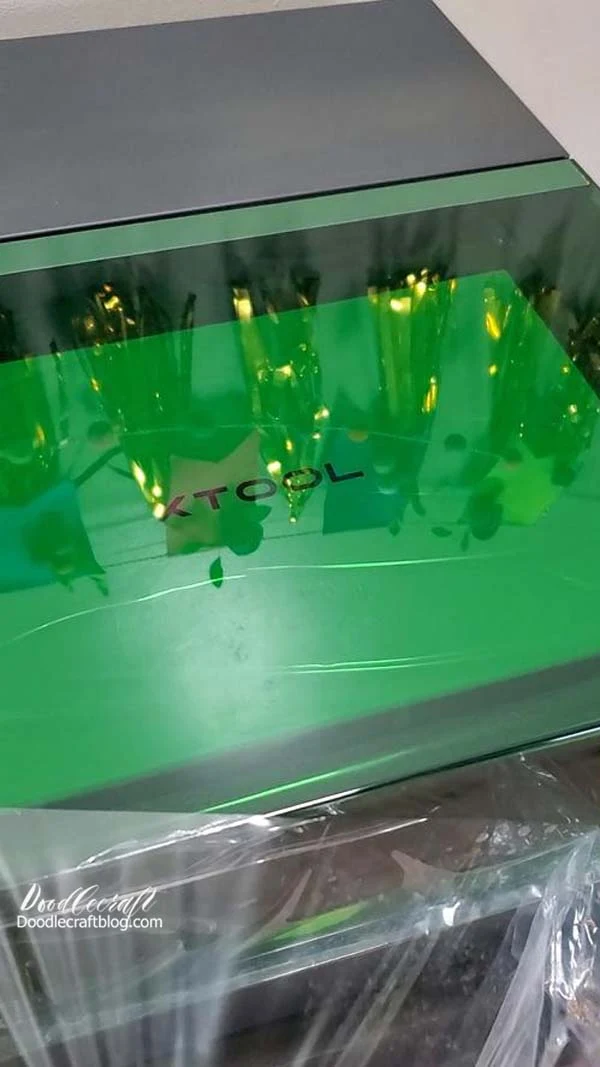

First Step: Open the Box.

Follow these easy steps to get started: Begin by opening up the xTool box.

This sounds silly, but my xTool sat in its box for 2 months before I was brave enough to open the box.

This awesome and cutting edge laser beam machine is made for USERS!

It's great for laser cutting beginners, so don't even be a little bit afraid.

Open up the box and unpack it carefully on a large table.

Everything is included to begin working with the laser cutter: instruction book/user manual, the power cord cable, triangular prisms or honeycomb and vent.

Setup the xTool S1 Laser Cutting Machine:

Next Step (2): Setup the xTool.

Ideally the xTool will need a window to vent out of.

If you don't have a window, there are vent boxes that you can vent into and filter the air.

The xTool machine needs a level surface to sit on.

Note where the cords and vent come out of the back of the machine, the air assist is built right into the xTool S1.

Storage space for extra accessories, like the Rotary Attachment (RA) and all the materials is super important too.

Make sure you have a level surface big enough to fit the bottom of the machine.

Here's the FULL xTool S1 Set Up Guide from xTool

1. Remove the packaging inside the xTool S1.

First thing is to remove the limit pieces from the working area that prevent shifting during shipments.

These parts prevent shifting during shipping and need to be unscrewed with the included screwdriver.

2. Install the Laser Head Module

- Open the lid and move the beam to an accessible center position.

- Connect the cable and the tube to the laser module.

- Align the locating pin on the back of the laser module to the hole on the linear guide block. Attach the laser module to the linear guide block. After inserting the locating pin, slightly lower the laser module to lock the locating pin into the slot.

- Adjust the laser module to make the two holes on the top panel align with the tapped holes on the linear guide block. Then, hold the top of the laser module in position and use screws to fix the laser module.

3. Install the distance sensor.

Initially I struggled with this. Install the distance sensor when the machine is powered off.

The pin can rotate like a screw so that the top of the pin is just enough to trigger the mechanism when sensing the distance.

4. Install the smoke exhaust pipe and vent it out the window or into the air filter box.

5. Connect the power cable from the machine to the outlet.

6. Insert the USB key in the USB Port in the back of the S1.

7. Check the emergency stop button.

8. Turn on xTool S1.

How Much Space does xTool Machines Take up?

Size of the Machines:

The size of these affordable laser cutters varies by models--do you have space in your craft room for a new machine?

The new xTool M (M1 Hybrid laser and blade) has the smallest foot print 22x18x9 inches without riser--it's a perfect choice--it also has a blade cutter for vinyl, HTV and other crafting!

The xTool S1 20W or 40W is 30x22x7 inches, without a riser or conveyor (for extra long materials)--Most powerful diode laser means maximum engraving speed and thicker materials!

The xTool P2 is 40×25×10.6 inches without metal base risers or conveyors--best part--it can cut different types of materials, including all acrylic!

You can invest in the riser base, honeycomb panel and other things as you go. (Or get the bundle that includes them!)

Setup the xTool S1 Laser Cutting Machine:

Step 3: Use the xTool.

Once your xTool machine is set up in your workspace, it's time to use it on your first project.

Download the xTool Creative Space Software (XCS).

Once the software is installed, connect the S1 to the computer with a cable.

Then enable the WIFI settings on the machine for wireless work going forward!

Begin using xTool with this simple first laser project:

- Place a piece of corrugated cardboard in xTool and use the magnetic clamps to hold it in place on the honeycomb. (if you don't have the honeycomb, place a piece of aluminum foil on the base of the machine and set the cardboard on top of that)

- Select the laser area on the XCS software (every xTool machine is a little different, so play around with it)

- Select a simple shape from the tool bar in XCS.

- Select it to cut, and typically the recommended settings for the material works great.

- Then click the process button.

- Click the start button on the machine to begin laser processing.

- Let the machine cut a simple shape from cardboard.

- It should just take seconds to see how powerful and awesome this laser cutter is.

- Remove the cardboard and examine the edges.

- If it didn't cut smoothly, try again.

- Do all your first test cuts with cardboard before using pricier materials.

What Kind of Files does xTool use?

XCS (xTool Creative Space) currently supports SVG, DXF, PNG, JPG, JPEG, and BMP file formats.

XCS is a really easy to use software program that takes just a bit of clicking around to familiarize yourself with.

What is Peng Sheng?

Peng Sheng for xTool is grease used in the xTool for lubricating moving parts like the belts.

Preserving optimal functionality of the xTool laser cutting machine necessitates regular maintenance and lubrication.

This routine upkeep ensures smooth operation, prolongs machine life, and guarantees precision in cutting tasks.

What are the Magnetic Clamps?

These magnet bar clip things come with the honeycomb base that goes inside the xTool machine as a work surface.

The magnet clamps are just that. They are made to hold the material in place while the laser does its work.

Step 1: Using the Magnetic Clamps with xTool

The wire is used for lifting the magnet out of the honeycomb when you are ready to move it.

Step 2: Slide Magnet in Honeycomb

To use the clamps, just slide the square magnetic part of the clamp into the hole of the honeycomb.

Step 3: Magnet Holds Materials in Place

The metal bar is placed on the material for cutting, just a slight edge needs to hold it down.

It's pretty secure, because the magnet is really strong!

When finished with the cut, just lift up on the wire and lift it out of the honeycomb or just twist it around so you can remove the material cut.

xTool M1 Hybrid Laser Cutter and Blade Cutting machine

Can the xTool M1 cut Acrylic?

Yes and No.

The xTool M1 is NOT ABLE to cut clear, white, blue, mirrored and transparent colors of acrylic.

They can cut cast acrylic with varying degrees of success. (Check out this post cutting acrylic with M1)

Black acrylic is the easiest to cut.

Can't engrave clear glass, (although some people find their way around this by painting the glass with black tempera paint).

Can the xTool S1 cut Acrylic?

Yes and No.

The xTool S1 is NOT ABLE to cut clear, white, blue, mirrored and transparent colors of acrylic.

They can cut cast acrylic with varying degrees of success. (Check out this post cutting acrylic with S1)

Black acrylic is the easiest to cut.

Can't engrave clear glass, (although some people find their way around this by painting the glass with black tempera paint).

Which Laser Cutter Should I Buy?

Various laser cutters cater to diverse needs. Is this your first time with a laser machine?

CO2 laser cutters excel in cutting and engraving organic materials like wood and all colors of acrylic.

Fiber laser cutters, ideal for metals, use fiber optics for precise and efficient cutting...very large and very expensive.

Diode laser cutters are compact and suitable for small-scale projects, great for wood and cast acrylic in certain colors.

Each type offers specific advantages, empowering users with options to match their materials, project scale, and desired precision in the world of laser cutting.

*PRO TIP: I've seen many people online very upset that they purchased a laser cutter and only found out afterwards that they couldn't cut acrylic.

If laser cutting all the colors of acrylic (including clear) is your goal, YOU HAVE TO PURCHASE A CO2 LASER, they just have a higher cutting capacity at an additional cost.

Diode lasers (like the M1 and S1) can cut a lot of colors of acrylic, but do have limitations--no clear, white, blue, transparent, translucent and mirrored...struggles with some colors but can successfully cut them after a few passes.

xTool Machines: (affiliate links)

xTool F1 Portable Laser Cutter

xTool S1 20W or 40W ( I have the 20W--see this post)

xTool M1 10W Deluxe RA2 (rotary tool attachment) Pro (this is the one I have--see this post)

I always suggest getting a bundle, so you get the machine, the RA2 and a materials pack to get making things right away.

Let's just sum this up quickly:

If you have the SPACE and the MONEY, buy the xTool P2.

If you don't have the MONEY, buy the xTool S1.

If you don't have the SPACE or the MONEY, buy the xTool M1.

What is the Best Laser Cutter Software?

xTool Creative Space or XCS is awesome software that interfaces beautifully with the xTool Laser Cutting Machine.

xTool execs are constantly listening to the suggestions of users and improving the software!

It's FREE to install and use, it comes with a bunch of free shapes and designs ready to use.

XCS is easy to learn and get comfortable with, you can import most file types too. (SVG, PNG, JPEG and DXF)

It is all I use with my xTool S1, I have no complaints!

Some people like to use Lightburn.

Lightburn is advanced laser software for designing, editing, and controlling laser cutting machines.

Its intuitive interface allows users to create intricate designs, import various file formats, and precisely execute laser cutting tasks.

It costs additional money.

I have never used it and don't know much about it.

Can you Make Money with xTool?

Yes--you can make money!

Laser Cutting can be a lucrative side hustle, hobby or small business.

Check out this post on Starting a Laser Cutting Business.

Leveraging a laser cutting machine for profit involves offering customized services, crafting unique products, and marketing creatively.

There is a lot that goes into starting a money making laser cutting business, but read through the post and see if it's the right direction for you.

That's it!

I hope you liked this comprehensive beginners guide to the xTool S1 and Frequently Asked Questions.

I tried to make it detailed for those that need deep details...and make it bullet pointed with great pictures for those of us that just scroll through words.

What will your next project be? Check out these laser beginner ideas here!

If you have any questions that weren't covered, leave them in the comments and I'll follow up with you in the coming weeks!

Happy Laser Cutting!

Like, Pin and Save!

Check out these xTool posts too!

Everything you need to know about the xTool S1

Here's a list of laser engraving ideas and 20 things to make here:

.jpg)

.jpg)

.jpg)

-min.jpg)

-min.jpg)

.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

.jpg)

-min.jpg)

.jpg)

-min.jpg)

Comments